-

Мобильная дробилка

- конвейерные запасные цепи

- совокупный шлифовальный станок

- природные ресурсы каолин

- каталог дробилки австралийской дробилки

- пневмодробилки

- щековая дробилка с б продажа

- Hero Factory коды ползучести дробилок

- дробилки для угля украина

- стоимость проекта завода по производству гуаровой камеди

- ncasseur haute ncassage

- дробилки для производства песка обработка материалов

- Соне дробилка отчет по проекту

- небольшая шаровая мельница для измельчения

- как устроен вибрационныи грохот

- купить гризли мельница для продажи

- Дигунакан Батубара дробилка

- щебеночный завод в Великобритании

- каменная дробилка завод в индии avilble

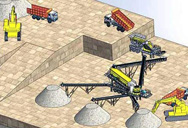

- Дробилка Добыча карьер

- шахты energy saving ball mill

<дробилки для продажи Канаде Диапазон серии

(PDF) Energy Efficient Ball Mill Circuit - ResearchGate

2013.7.15 PDF The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment

Read More

Research Progress of Energy Saving and Consumption

Accurate ball make-up technology has been widely used in mines in China, which has reduced the power consumption and ball consumption of ball mills to varying degrees

Read More

Energy conservation and consumption reduction in

2023.11.1 This paper presented an industrial validation test for reducing the energy consumption of grinding operations using a ceramic media stirring mill instead of a two

Read More

Breaking down energy consumption in industrial

2017.1.17 The grinding process in ball mills is notoriously known to be highly inefficient: only 1 to 2% of the inputted electrical energy serves for creating new surfaces.

Read More

Energy Saving Ball Mill - xinhaiepc

Large double row self-aligning roller bearing with low friction force is used to replace sliding bearing, which is easy to start and saves 20-30% energy. Cylindrical energy saving grid ball mill is lined grooved ring plate which

Read More

Energy Efficiency - Solutions - Ball Mill WEG

Solutions Ball Mill Ball Mills Flexibility and productivity Ball Mills are widely used in the ceramic and mining industries, where the grinding process requires strict grain size

Read More

The energy efficiency of ball milling in comminution

2002.11.1 The main way to improve the performance of ball mills is to optimize the operating modes of the electric drive and mill equipment, to ensure stable operation of

Read More

High Energy Ball Mills Instead of Planetary Ball

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within a very short process time. The high energy input is a

Read More

4-064 Yun-Hsun Huang Estimation of energy efficiency

The annual energy savings (ES) of an EET in year t for one scenario (Sc) are calculated according to the specific saving potential (sp), the diffusion (Diff) of the EET in year t and

Read More

Best energy consumption - International Cement

2015.2.16 Grinding energy was approximately 50 per cent of the ball mill and the drying capabilities allowed direct processing of materials of up to 20 per cent moisture content. The main energy issue was the high power

Read More

A specific energy-based ball mill model: From batch grinding

2016.2.1 Introduction. A specific energy-based size reduction model for batch grinding ball mills has been developed (Shi and Xie, 2015). The objective of this work was to overcome the limitations in the existing JKMRC (Julius Kruttschnitt Mineral Research Centre) perfect mixing ball mill model, including the use of a set of default breakage

Read More

Ball Mill - an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision

Read More

节能球磨机_百度百科

节能球磨机包括球磨机旋转滚筒、支架底座和驱动装置和附件等,节 能球磨机旋转滚筒地步固定有支架底座,旋转滚筒上的出料位置安装有细料筛, 驱动装置设置在节能球磨机旋转滚筒的外部。相比传统球磨机采用滑动轴瓦,摩擦阻力大,功耗高,据统计,因摩擦功耗损失约占电动机功率的17%~23% ...

Read More

Ball Milling in Organic Synthesis: Solutions and Challanges

2011.3.2 It is rather recommend changing reaction time than frequency. Start with 75-100% of the maximal operation frequency of the ball mill. The thermal stress for the reactants could be reduced by using cycled mode: mill for a. specific amount of time – 5-10 min pause – start milling again and repeat the procedure for the required amount of time.

Read More

Analysis of dynamic similarity and energy-saving mechanism

2015.3.1 Energy-saving analysis of the planetary ball mill. The similarity criterion of the power is defined as: (31) YEv = N 0.5 ρ vL 2 v 2 where N is the shaft power that acts on a single vial, ρ is the characteristic density of the outputting powder, and v is the characteristic velocity of the outputting powder. In Eq.

Read More

The energy efficiency of ball milling in comminution

2002.11.1 In terms of this concept, the energy efficiency of the tumbling mill is as low as 1%, or less. For example, Lowrison (1974) reported that for a ball mill, the theoretical energy for size reduction (the free energy of the new surface produced during grinding) is 0.6% of the total energy supplied to the mill setup.

Read More

Analysis of dynamic similarity and energy-saving mechanism

2015.3.1 Finally, depletion efficiency of the powder effect was proposed to interpret quantitatively the energy-saving mechanism of the planetary ball mill. However, Yan’s work is purely hypothetical. As such, it lacks verification of adequate accepted theory and experimental data. Thus, further studies are carried on in this paper.

Read More

The energy efficiency of ball milling in comminution

2002.11.1 In terms of this concept, the energy efficiency of the tumbling mill is as low as 1%, or less. For example, Lowrison (1974) reported that for a ball mill, the theoretical energy for size reduction (the free energy of the new surface produced during grinding) is 0.6% of the total energy supplied to the mill setup.

Read More

Energy Use of Fine Grinding in Mineral Processing

2013.12.18 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor. While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s

Read More

Energy and Cost Comparisons of HPGR-based

5 天之前 Figure 2—HPGR ball-mill circuit. To determine whether the novel HPGR-stirred mill circuit arrangement could achieve energy savings in comparison to conventional SAG mill-based circuits, a pilot-scale study

Read More

Market Surveys on Energy-saving Ball Mill - CSDN博客

2012.3.1 Market Surveys on Energy-saving Ball Mill. Ball mill design is high technologies content material, and design of ball mill sizing has strict standards. Efficiently strengthen the fineness of grinding is one of the essential facet in the complete processing positions, portion of grinding is cost greater inside the dressing plant, how effective ...

Read More

(PDF) Grinding in Ball Mills: Modeling and Process

2012.6.1 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made ...

Read More

Ball Mills - Laboratory Grinding Mill Latest Price,

Ball Mill. ₹ 2,50,000/ Piece Get Latest Price. Our organization is one of the trusted suppliers of industrial Ball Mills.T hese products are used for dry and wet grinding of colors and paints. These are offered with additional gears pinions

Read More

Market Surveys on Energy-saving Ball Mill - liajones - 博客园

2012.3.1 Energy-saving ball mill could be the key gear for grinding immediately after the crushing procedure, which can be broadly made use of within the manufacture industries, just like cement, silicate, new constructing materials, refractory materials, fertilizer, ferrous

Read More

Energy Efficiency Analysis of Copper Ore Ball Mill Drive

2021.2.26 Energy savings may also be found in the ball mill drive systems. In the scale of a processing plant, the electric motors of these drive systems account for 95% of the total electric energy demand . Therefore, the type of the motor used has a significant influence on the efficiency of the drive system.

Read More

Simulation of ball motion and energy transfer in a

2012.6.12 Chin. Phys. B Vol. 21, No. 7 (2012) 078201 and Loiselle et al.[19] used calorimetry to test the im- pact speed of the SPEX mill, and obtained results of 3.8 and 3.6 m/s, respectively. Contact temperature increases with the impact velocity in the

Read More

Ball Mill Balls - Manufacturing Of High Quality Ball Mill Ball

Ball mill balls. Ball mill balls are a type of ball used in ball mills, usually made of high-hardness materials such as steel, ceramics, hard alloys, etc. Ball mill steel balls is an important part of the ball mill, its main function is to carry out the grinding operation in the ball mill, and the material is crushed into the required size.

Read More

High-efficiency and energy-conservation grinding

2022.1.1 A pilot-scale grinding technology of ceramic medium stirred mill was proposed in this study. Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were ascertained as follows: material ball ratio of 0.7, ceramic ball medium size ratio (10 mm: 15 mm: 20 mm = 3:2:5), stirring speed of 110

Read More

Energies Free Full-Text Increasing Energy

2020.12.21 Energy consumption in ball and rod mills reaches up to 10–20 kWh per ton of rock. According to the study prepared by the U.S. Department of Energy the biggest potential for energy savings in all of

Read More

7-Ways to achieve energy saving in Cement

2016.6.3 Traditional mill energy utilization is low, a lot of wasted effort, and the corresponding transformation of energy-saving technologies should be grinding process basic tasks, which all need to ...

Read More

The operating principle of the ball mill

2017.2.8 Energy is mainly consumed on the wear of grinding balls and mill housing, friction; heating the material etc. The advantages of ball mill there are large unit capacity, achievement degree of fineness

Read More

Ball Mill Working Principle And Main Parts Pages

2015.7.14 Besides, SBM energy-saving mining ball mill can offer a grinding solution near the quarries. So it can significantly reduce the operation cost and make mining activities more convenient. Main Parts Of Ball Mill. The most widely used in the production of a variety of ores are wet overflow ball mill and wet grate ball mill. Aside from common ball ...

Read More

Ball milling: a green technology for the preparation and ...

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the prep-

Read More

Energy Saving Ball Mill Market Size Reveals the Best

2023.12.22 {Provide Informative Summary on Energy Saving Ball Mill market research reports specific to market conditions. Also, give a Brief overview of the report’s main findings and recommendations. Write

Read More

Energy Saving Ball Mill - xinhaiepc

Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding. Large ore outlet and large capacity; The mill with diameter below 2.1 meters adopts whole machine frame, which is convenient for civil construction and equipment installation. ...

Read More

Innovation is An Eternal Topic of the Mill Field - CSDN博客

2019.9.22 As we all know, the aim of innovation is to save energy and improve efficiency.let me introduce the next two kinds of mills to analysis them from the perspective of innovation. The Energy-saving ball mill is used for fine grinding operations, but also often used for rough grinding operations. ...

Read More

Ball Mills - 911 Metallurgist

2017.2.13 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

Read More

Improving Energy Efficiency Via Optimized Charge Motion

2006.7.21 @article{osti_922135, title = {Improving Energy Efficiency Via Optimized Charge Motion and Slurry Flow in Plant Scale Sag Mills}, author = {Rajamani, Raj K}, abstractNote = {A research team from the University of Utah is working to make inroads into saving energy in these SAG mills. In 2003, Industries of the Future Program of the

Read More